Three-Layer Walls

Three-layer precast concrete walls are manufactured even at the factory with insulation material, the thickness of which is selected to resistance wished by the customer. In addition, precast concrete walls feature tightness and heat accumulation property, therefore to heat the building less energy is consumed.

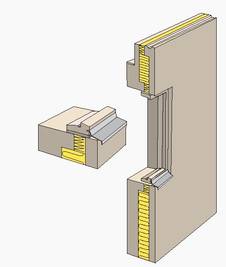

External three-layer wall slab consists of three layers:

- internal load-bearing precast concrete layer, the thickness of which is 100 mm to 150 mm;

- internal thermal insulation layer, the thickness of which is 50 mm to 300 mm;

- external finishing precast concrete layer, the thickness of which is 80 - 100 mm.

Thermal resistance of three-layer walls from Betonika UAB reaches 8.5 m2K/W having taken into account the ties, connecting wall layers, while most often applied to residential construction value is 5m2K/W.

Table 1 Wall (multi-layer) slab resistance, having taken into account wall layer connecting ties

| Insulation thickness, mm | Thermal resistance, m2K/W |

|

Stone wool or neopor, λ=0.036W/mK |

|

| 150 | 3,8 |

| 180 | 4,6 |

| 200 | 5,0 |

| 250 | 6,1 |

|

Polyurethane foam board (IP PIR023), λ=0.023W/mK |

|

| 30 | 1,4 |

| 50 | 1,8 |

| 100 | 3,5 |

| 150 | 5,1 |

| 200 | 6,8 |

| 250 | 8,5 |

Internal and external precast concrete layers are joined by means of flexible ties from stainless steel, through which the load from the external layer self-weight is transferred to the internal load bearing layer.

Three-layer wall optimal length - 7 m, height - 3 m, overall wall width 430 mm, fire resistance - 90 min. On customer‘s request, potential maximum dimensions can be: length – 12 m, height – 4.5 m, overall wall thickness - 550 mm, reaction to fire - 180 min. Precast concrete production items recommended for residential construction should not be longer than 7.5 m.

External three-layer wall connection joints are sealed using a sealant, resistant to joint shifting. Sealing substance colour is matched to the facade.

External three-layer wall layer is moulded at the bottom of the mould – this ensures accuracy of dimensions and possibility to use various materials. You may choose various surfaces of precast concrete facade: clinker, Reckli®, graphic concrete, coloured concrete or exposed texture concrete.