TT-Type Slabs

TT-type floor slabs are used to bridge large spans and in the case of considerable loading. The underside of TT-type slabs is smooth. Nominal widths of TT-type slabs are 2400 mm and 3000 mm. On customer‘s request, slabs of lesser width can be manufactured as well, minimum width - 1500 mm. The ends of precast concrete elements can be notched to profile a rigid joint or reduce the overall height of the structure. An extra concrete layer ensures shearing force transfer to the adjacent elements and work of the horizontal diaphragm. The fire resistance of standard TT-type slabs is within 60-180 minutes. Anchor rods are concreted into the walls of slabs.

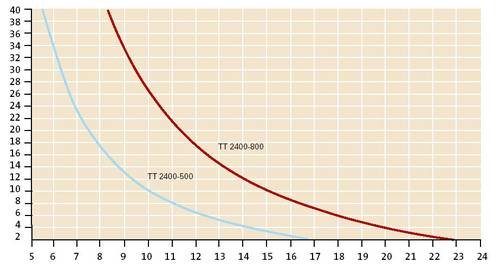

Fig. 1. TT-type slab standard profile

Technical Characteristics

Table 1 Characteristics of TT-2400 slabs

|

Profile |

h mm |

b mm |

b1 mm |

b2 mm |

b0 mm |

Weight kg / m2 |

|

Fire resistance 60 min |

500 |

2390 |

1120 |

635 |

120 |

261 |

|

Fire resistance 90 min |

500 |

2390 |

1150 |

620 |

150 |

287 |

|

Fire resistance 120 min |

500 |

2390 |

1200 |

595 |

200 |

332 |

|

Fire resistance 180 min |

500 |

2390 |

1260 |

565 |

240 |

380 |

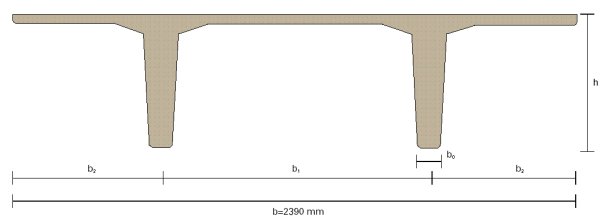

The curves of operating performance of precast concrete structures show change in TT-type slab load bearing capacity depending on opening length.

Fig. 2. Operating performance curves of TT -2400 slabs

Joints

To connect TT-type slabs, joints are necessary that are designed by Betonika UAB designers. The joints between TT-type slabs and supporting beams are installed using reinforcement of the upper levelling concrete layer or rods, attached to embedded parts.

Lateral joints with wall slabs or joints between adjacent TT-type slabs are obtained interlacing reinforcement mesh or welding to each other embedded parts, existing in the edges of slabs.

Drawing of joint assemblies you can find here.

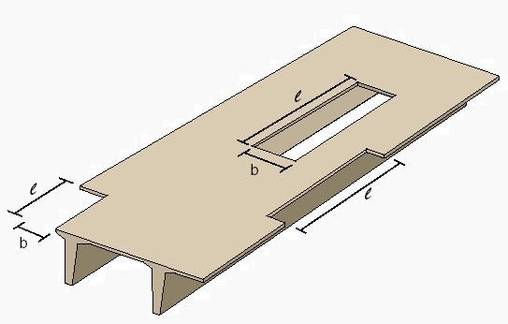

TT-Type Slab Recesses and Holes

In the TT-type slabs, recesses can be profiled. In the edges, round openings can be made for process piping as well. Position and dimensions of recesses and openings must be identified in advance, because they reduce the load bearing capacity of a slab.

Fig. 3. Recesses can be profiled in TT-type slabs

Table 2 Maximum width of recesses in TT-type slabs

|

l / b |

TT - 2400 |

TT - 3000 |

|

Centre |

1000 / 630 |

1000 / 930 |

|

Edge |

1000 / 320 |

1000 / 460 |

|

Angular cut |

1000 / 320 |

1000 / 460 |

Storage and Transport

The TT-type slabs are stored on semi-soft (e. g., wooden) battens, which are placed under the ends of the slab. When stacking slabs, the battens must be in one line above each other. In the same manner the slabs must be stacked during transportation. In the longitudinal edges of the slab, four lifting lugs are concreted. During hoisting, the angle between the straps must not exceed 90o.